Gemini South's Mirror Glistens

13 October 2010

pristine new coat of protected silver now glistens on the Gemini South primary mirror (M1) as part of a routine shut-down on Cerro Pachón in Chile (geminiann10018a). The coating, applied in the Gemini South coating chamber on October 8th, 2010 is thought to be one of the “best ever achieved at Gemini” according to Gemini Optics Engineer, Tomislav Vucina. The planned 28-day shut-down (including engineering checks on the sky) which began on September 27th also includes maintenance of the Cassegrain wrap, the acquisition and guiding unit, the adaptive optics fold mirror, and instruments.

“A late-spring snowstorm delayed some of our critical preparations but in the last couple weeks we were able to make up that lost time,” said Gemini Systems Engineer, Brian Walls (geminiann10018b).

The Gemini coating process uses “sputtering” to lay-down the ultra-thin 4-layer coatings in the giant coating chamber (geminiann10018c) in the basement of the telescope (Gemini has an identical facility on Mauna Kea for the Gemini North telescope). According to Vucina, "The silver layer on the mirror has a thickness of 1145 Ångström Units, which means 1000 times thinner than a human hair..." Over the past decade the engineering staff at Gemini have perfected the technology which allows the application of the protected silver coatings which have proven to last up to 4-times longer than traditional aluminum coatings used at all other major observatories. The silver is also more reflective than aluminum at wavelengths longer than 450nm, which provides more efficient observing through most of the optical and infrared bandpass. “We all take great pride in the unique coatings we produce at Gemini Observatory and I think it reflects well on every single individual who contributes to make this happen,” said Walls.

In addition to the continued refinement of coating procedures, many new safety protocols were implemented by the 30+ staff, which included many individuals from the Gemini North telescope in Hawai‘i. According to Gemini’s Safety Program Manger Rodrigo Sandoval, “Our goal is to make this difficult procedure as safe as possible. When you have 24 tons of glass hanging 4-stories overhead and a wide-range of chemicals, high voltage and staff scrambling to meet deadlines you have to be extra vigilant to stay safe.” There were no serious safety issues during the entire coating procedure.

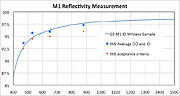

Preliminary tests show that the reflectivity of the coating is significantly better than specified by the requirements, as geminiann10018d shows. The mirror cleaning and coating process also reduces the emissivity of the mirror, thus reducing the undesirable background and making observations more sensitive.